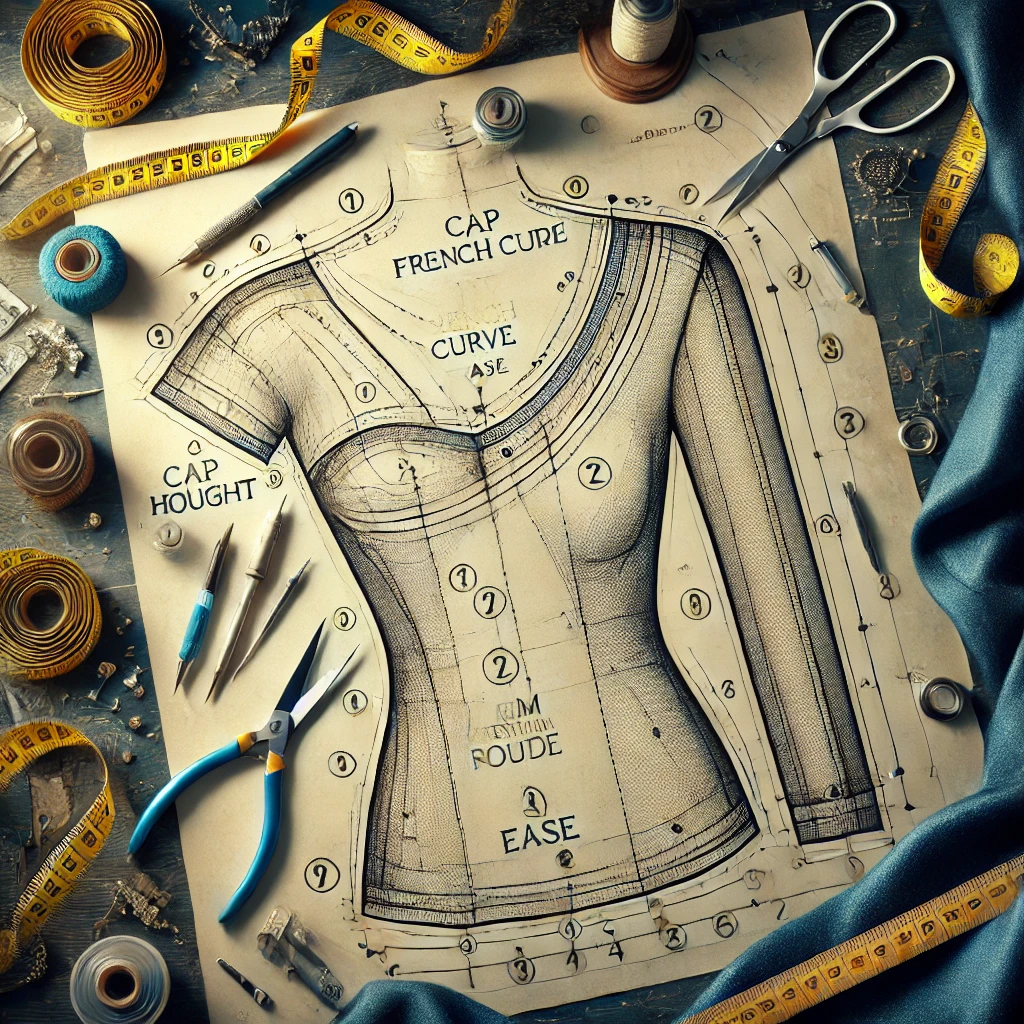

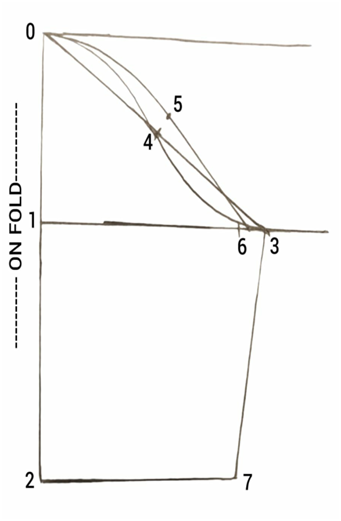

Creating a well-fitted sleeve pattern is essential for achieving a professional finish. Follow these steps carefully for accurate results:

1. Sleeve Panel Construction

- Cap Height: The cap height will differ depending on the size of the sleeve:

- Small: 3.5 inches

- Medium: 3.75 inches

- Large: 4 inches

Mark the cap height as 0-1.

- Full Sleeve Length: Measure and mark the full sleeve length as 0-2.

2. Arm Round & Ease

- Arm Round Measurement: Measure half of the armhole circumference and add ease (1-3).

- Joining Line: From point 3, draw a line to 0, connecting the top of the sleeve to the armhole curve.

3. Marking the Curve

- Divide the Sleeve: Take the length between points 0-3 and divide it by 2. Mark this point as 4.

- French Curve Drawing: Use a French curve to draw a smooth curve from 0 to 4.

- Position the French curve at the 8-inch mark on the ruler. Place a marking line at point 0, then move it equally towards point 4 to create a smooth, even curve.

- Repeat for the Other Side: Repeat the same process from point 4 to 6 to ensure symmetry.

4. Adding Ease and Further Markings

- Adding Ease: From the point marked at 1/2 inch, label it as point 5.

- Place a marking line at point 0, moving equally towards point 5 to create another smooth curve.

- Mark Additional 1/2 Inch: From point 3 to 6, mark another 1/2 inch, and label it as point 6.

- Join the Lines: Now, connect points 5 to 6 with a smooth line.

5. Sleeve Opening and Joining the Lines

- Marking the Sleeve Opening: For the sleeve opening, mark point 2-7 and add an additional 0.5 inches of ease.

- Joining the Sleeve Lines: Finally, join points 3-7 to complete the sleeve.

6. Cutting the Sleeve Pattern

- The entire sleeve pattern should be cut on the fold to ensure a seamless design.

By following these detailed steps, you’ll create a perfectly shaped sleeve pattern with ease and precision. Be sure to check the symmetry and smoothness of your curves to ensure a professional finish.